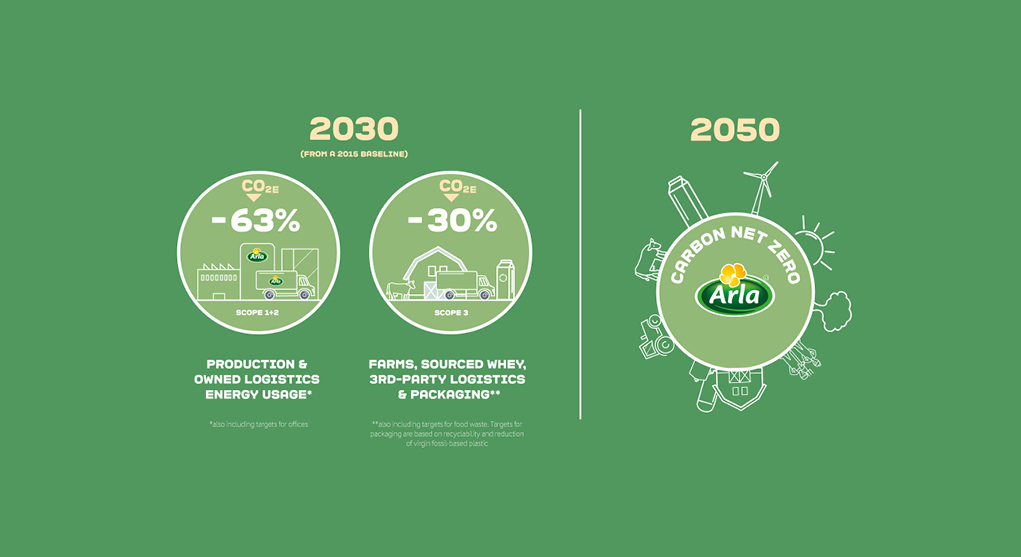

Ensuring the safety and quality of our products through shelf life requires the use of complex packaging types. Nevertheless, we remain committed to our two primary goals in the packaging areas: 100% recyclable packaging for own-brand products by 2025 and the complete phase-out of fossil-based virgin plastic by 2030.

The Arla Group ambition is that all packaging materials – paper, cardboard, plastic and metal – should be fully circular in 2030.

All our current packaging materials are today designed to be recyclable. We are also limiting our use of fossil-based virgin plastic where possible. Food contact materials are the biggest challenge in this area as there is still no alternative to an inner layer of virgin plastic. We continue to explore potential solutions in collaboration with Arla.