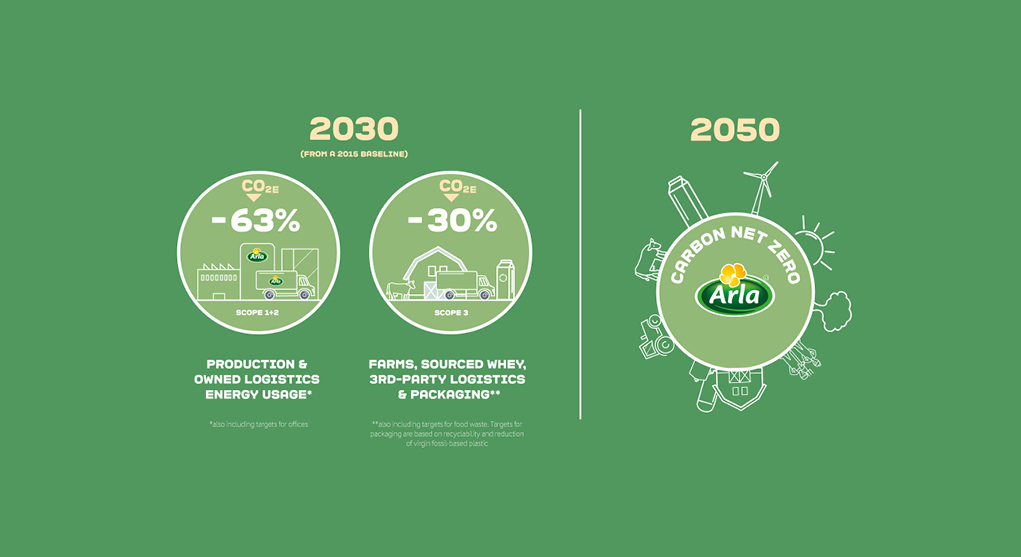

Towards carbon net zero

Our modern production sites consume high volumes of energy to ensure the purity, quality and safety of our ingredients. And we continue to expand them in preparation for future global demand.

This is why our climate strategy is so important. As our business grows, we aim to reduce production-related emissions to carbon net zero by 2050. Our intermediate goal for 2030 is to achieve a 42% reduction in emissions compared to our 2015 baseline.