Our responsibility for a stronger tomorrow

At Arla Foods Ingredients, we strive to develop and manufacture all our ingredient solutions in the most sustainable way possible.

We have to ensure we put our raw materials to best possible use, minimise our footprint on the global environment and make healthy nutrition accessible to consumers everywhere. For our colleagues, we must provide a safe, tolerant and inspiring workplace across our locations.

This requires that we focus on our entire value chain. Using the UN sustainable development goals as our guide, we identify what, where and how we can do better.

Stronger planet

Stronger people

Follow our progress

Every year, we publish a detailed overview of how we are progressing towards our objectives and the link to the sustainable development goals. You can find our latest progress report here.

Our contribution to the UN Sustainable Development Goals (SDGs)

The 17 SDGs are a source of inspiration and set the direction for the continuous improvement of our operations and long-term growth of our business. Although all the goals are related, there are some where we see the possibility to make a particular contribution through our value chain.

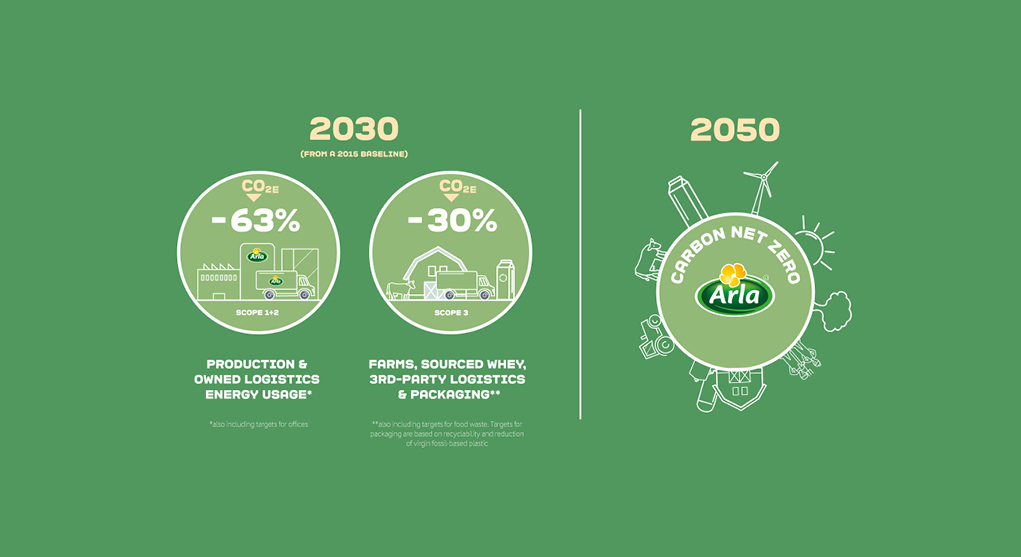

Our climate ambition

Arla Foods Ingredients is committed to the Arla Group ambition to reduce absolute scope 1 and 2 CO2e emissions by 63% in 2030 compared to our 2015 baseline. We will contribute to this target by driving the green transformation of our fully-owned production sites.

The Science Based Targets Initiative (SBTi) has approved this target as consistent with the Paris Agreement ambition to limit global warming to 1.5°C.

The group-level target for scope 3 emissions is a 30% reduction by 2030.

We are working with the Arla group to update this target in line with the SBTi Forest, Land and Agriculture (FLAG) guidelines.